This article is part 3 in a multi-part series, please refer to the previous publications for an introduction to Tiny Homes and the history of tiny homes

Tiny Home Builder Examples

Although the picture for tiny homes may seem bleak, I’ve had first-hand experience with a number of builders over the past several years:

- Haus: Though technically a US-based company, Haus predominantly imports its materials from several European and Asian suppliers. The company’s supply chain is kept confidential, which is somewhat frustrating when trying to determine how and where these units are made. Additionally, any real inspection and certification process would be almost impossible given how opaque their manufacturing process is. Upon touring the “MicroHaus” product in San Diego, it is evident that the units are indeed as advertised; tiny homes designed in an ultra-modern minimalist aesthetic with multiple windows and a composite casted interior. The integrated technology is also as advertised, with some very attractive features embedded in the home such as integrated lighting, heating, and water purification. The marketing push for the company is largely in the “un-permitted” market for uses such as accessory buildings for single family homes, vacation rentals, and off-grid getaways. Given the increased scrutiny around unpermitted uses for tiny homes, and the relatively complicated and non-disclosed nature of the Haus manufacturing process, getting these units into a large scale housing application will be difficult, if not impossible. Regardless, the technology and design of the homes is undeniably impressive, and hopefully a more transparent and domestic manufacturing process can be created to allow for greater market adoption[1]

The ”Microhaus” tiny home unit (Haus.me)

- Azure Printed Homes – Founded in Los Angeles in 2021, Azure is the first home building company to make use of an extruded plastic technology as the primary means of production and manufacture. The company production location is based in Los Angeles, meaning all aspects of the home’s construction take place domestically and could be third party inspected for the purposes of obtaining residential dwelling approvals (although, as of this writing, no such approvals have been obtained for the company). Although the extruded plastic system shows promise as a novel (and recyclable) building product, the system is fundamentally limited as it still relies in large part on conventional construction methods to create a finished product. Regrettably the printed plastic components only make up a percentage of the exterior make-up of the home which is supplemented with conventional framing, and the entire interior of the homes must be finished with conventional products. Were the technology to be adopted by the larger manufactured home industry it would certainly be an interesting addition to the existing make-up of building systems, Azure in its current form will unlikely be able to product products at any meaningful scale or at a price point that is competitive with existing products[2]

Finishing out a newly printed Azure home (Product Profile X_180 | Azure Printed Homes)

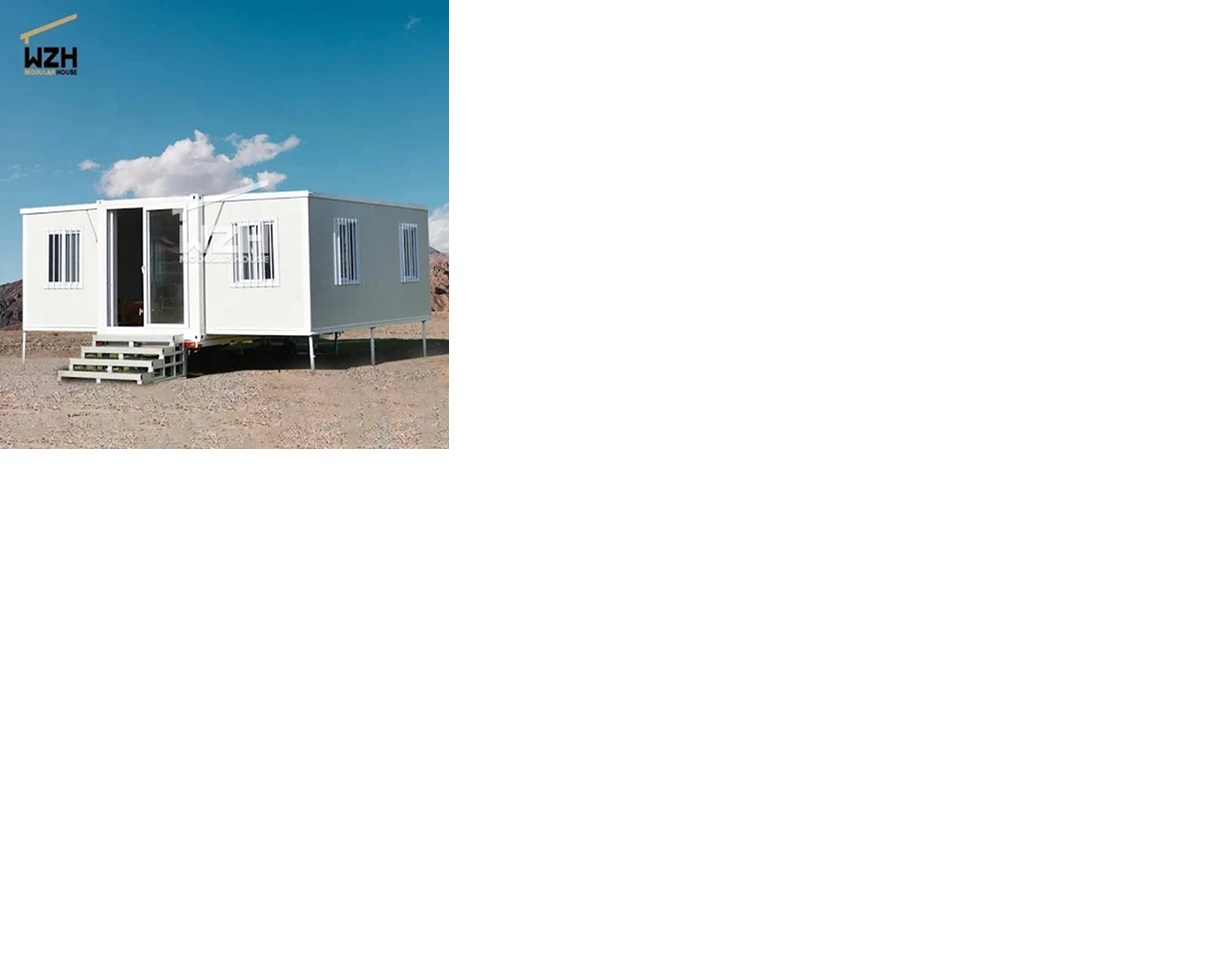

- Container Homes: There are multiple companies (mostly Chinese based) that are making use of existing container structures to fabricate tiny home type products. Upon visiting several of these factories in China it is evident that this technology is being actively deployed in numerous regions throughout the world, predominantly as worker housing in remote areas and in temporary construction situations. With the proper domestic partnerships, making use of these fabricated structures could show great promise as the requisite scale is already present and these structures are already being used in housing applications.

One of the many container home designs in use

Successful tiny homes are all about tech

Regardless of the managerial misguidance many of these companies seem to suffer, there is real and interesting technology being developed that can hopefully be leveraged into real, impactful, solutions to the affordable housing market. Some of these technologies include:

- Novel building materials: Several recent entrants into the tiny home marketplace are making using of an exciting array of new materials, including “printed” concrete tiny homes[3], extruded plastic exterior homes[4], and modern fiberglass shell homes[5]. As of this writing, none of these companies have yet been able to deliver a permitted structure ready to use as a full-time residence, but each of these technologies shows promise.

- Integrated renewable energy: The novel production methods of these homes, and corresponding target markets, has led to a proliferation of solar and battery technology used to power these homes. More than any of the innovations introduced by these builders, it is this technology that shows the most potential for integration into the existing manufactured housing infrastructure. Existing large manufactured home builders, provided they can validate the demand for such a product, can readily integrate the same type of renewable energy products into their manufacturing process.

- Novel production methodologies: Similar to the utilization of new building materials, these companies are also leveraging new technology to build these structures, including plastic extrusion instruments and 3D printers capable of largely automated assembly. While these technologies have a long way to go to achieve meaningful scale, it is promising to see them in use, even on a trial basis. Several companies, such as Haus, are taking advantage of existing technology in use in other industries (such as fiberglass ship-hull manufacture, structurally insulated panels, and composite panels) and applying them towards tiny home construction.

- Container homes: One especially interesting production methodology makes use of shipping containers to produce tiny homes, which takes advantage of a huge amount of existing infrastructure that already is easily manufactured, transported, and used internationally today. Leveraging all of this existing material brings tremendous possibility for rapid scale-up if a suitable development procedure can be identified.

- Compelling pricing: In some circumstances, these products are being marketed at a very competitive price point—you can even find tiny homes on Amazon at very attractive prices.[6] The reason for many of these discounted prices, however, is that most of these structures aren’t permitted for residential use, and (as previously discussed) the cost to convert/retrofit to legal use is substantial. Another factor impacting the price point is the fact that these structures are being sold “at the gate,” i.e., without transport, setup, utility connections, or inspections, which also adds significantly to their final cost. This is not to say that there isn’t any value in the low prices being offered by a lot of these homes. In fact, with the right design and implementation, many of these home can be used in a safe and legal manner while not drastically increasing the cost per unit. This, however, requires competent construction personnel who can take on a significant number of these structures at once in order to capitalize on scale economies that come into play.

[1] Models | haus.me

[2] Homes on Wheels | Azure Printed Homes

[3] Homepage | Azure Printed Homes

[4] Intelligent Machines that will Build Humanity's Future - ICON (iconbuild.com)

[5] haus.me | Autonomous Self-Sustainable Intelligent House

[6] Amazon Best Sellers: Best Tiny House Kits